Dr Martens factory tour

A couple of the weeks ago I was invited to visit the Dr Martens factory. This was something that dreams are made of - a shoe factory - not just any shoes - The shoes.

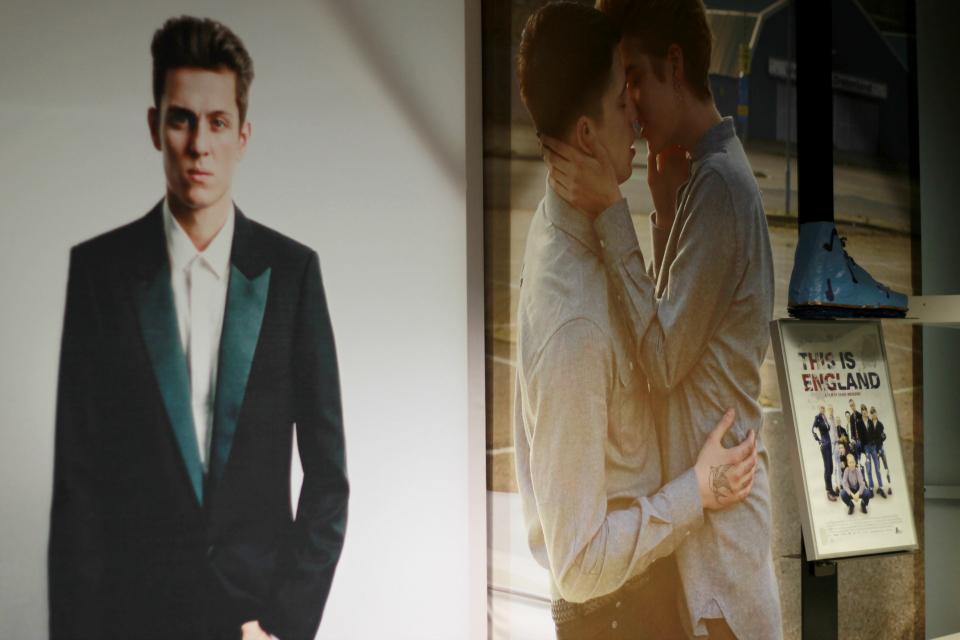

Little details in the factory really reflected the individuality of the brand- the staff all wore Dr Martens - either from past seasons or testing future samples - each test is for one month , after which the staff return the sample with a review which will decide if the production of the sample goes ahead. A cool juxposition to the overall's and work gear the factory workers are wearing when you look down and see a shiny pair of studded brogues in metallic colours.

The boots start of by being hand cut from the sheets of leather, before being sewn together effortlessly by the skilled ladies on one side of the room before heading over to the other side of the room where men await the pieces of leather to mould, before adding the sole, famous yellow thread & buffing the boot so that it shines. all by hand, all individually, each boot being passed from machine to machine, person to person - each worker with a skill to ensure each product is as perfect as the next.

I honestly would recommend going on a tour there to anyone who can- and despite the fact that only 2% of Dr Martens are made in England ( and therefore are more expensive ) - it definitely has made me want to buy a pair of Made in England ones next time I shop there. I wasn't sure what to expect as Dr Martens is such a strong British brand, and I wish that all of the boots could be made this way, but due to the skills involved in making these boots - many of them are made offshore - something the brand are looking at addressing by introducing apprenticeship schemes at the factory and showing the younger generation just how it is done. The day made me feel even prouder to own a pair of Dr Martens, the history is fascinating, the workers are breathtakingly knowledgeable & the amount of care and attention that goes into one single boot or shoe shows a real sense of pride.